transport

Perfect wash requires perfect water.

The wastewater recycling system treats trade effluent so it can be reused to wash again. It is applicable to all purposes in the passenger and freight transport sectors, e. g. washing of cars, trucks, trains, planes.

The wastewater is treated biologically with MBBR technology (Moving Bed Biofilm Reactor) without the use of chemicals. If you transport food and animals, we have a wastewater treatment plant that can treat the wash effluent before discharge.

WHAT YOU GET IF YOU CHOOSE A RECYCLING SYSTEM FROM US?

HIGH QUALITY OF THE RECYCLED WATER

Wastewater that has been treated by the system is as clear as drinking water. There is therefore no need to use drinking water for washing.

The system treats the wash effluent to this excellent quality over and over again.

EFFECTIVE & COST-SAVING

The system treats and recycles all wastewater that drains into the trench drain from the washing area. There is no discharge. Only in case that you run more water into the system than the volume necessary to compensate for the water loss during a wash.

You do not have to add any substances into the system to keep it working. The biological process takes care of itself. Morover, the system is odour-free and hence, contributes to a pleasant working environment in the area.

USE OF RAINWATER

Why pay for water when rainwater is for free? Water loos from washing (evaporation, etc.) is in our systems compensated by harvested rainwater.

The systems harvest rainwater from roofs or parking places. Outdoors rainwater harvesting tanks are insulated and frost-proof which ensures continual supply of rainwater during the winter period.

MINIMAL MAINTENANCE

The system does not require much of attention. It is self-cleaning, you do not have to clean it yourself. The water in the system does not have to be changed.

MOBILE

The system units are mobile and you can move it from one place to another. You can lift the unit with a forklift or a crane. You just have to drain it of water before you move it.

Less sludge & without an oil skimmer

The MBBR method used to treat the wastewater reduces the quantity of sludge by up to 80 %. For you it means that significantly lower costs for sludge removal and disposal.

The bacteria in the bioreactor ‘eat’ the oil that gets to the wash effluent during a wash. You save money for purchase and maintenance of an oil skimmer.

overall cost-savings for:

Drinking water

Wastewater discharge

Additional substances and bacteria

Purchase and maintenance of an oil skimmer

Sludge removal and disposal

Service

Chemicals

info about the MBBR system

DESCRIPTION OF THE SYSTEM

The system is built as a mobile unit where the floor frame is protected from rust by galvanization.

The housing of the unit is made of insulated sandwich panels.

Dimensions of a standard system are 606 x 244 x 259 cm (L x W x H).

The unit contains: a bioreactor, two or four sand filters, a storage tank and a control panel.

FLOW SCHEME IN THE SYSTEM

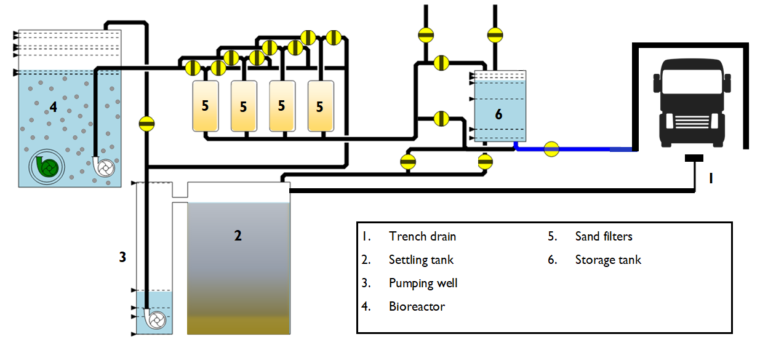

Wash effluents are diverted through a trench drain (1) to a settling tank (2) where particles such as sand and grit settle. The effluents run from the settling tank to a pumping well (3) from where it is pumped into a bioreactor (4). In the bioreactor, the effluents get treated using the, MBBR technology (read more about the technology here).

There are bacteria that under optimal conditions feed on the organic pollution in the wastewater. After that, the water passes through two or four sand filters (5) (the number depends on the pollution degree). The filtered water is pumped into a storage tank (6) and is ready to be reused. The water circulates in this closed loop endlessly.

In case of rainwater utilization

If the water loss from the vehicle wash is compensated by rainwater, the rainwater is pumped from a harvesting tank (7) to the storage tank (6). Rainwater can also be sent to the bioreactor in case it is necessary to treat it first.

Rainwater compensates the water loss in the system caused by evaporation and removal of the water from the washing area.

In case of non-existing underground settling tanks

If there are no settling tanks, the wash effluents are pumped from a collector up into a sand separator standing next to the system unit and separating liquids from solids. The liquids carry over into the bioreactor.

MBBR TECHNOLOGY

The MBBR (Moving Bed BIofilm Reactor) technology is used in the systems to treat the wastewater. There are bacteria that feed on the organic pollution in the effluent. They live on carriers that move around in the bioreactor.

This treatment is based on the same process as natural purification of water in rivers and streams. No chemicals are used to treat the wastewater. The bioreactor is aerated with a pump that also works as a water agitator.

You can read more about this technology here.