PRODUCTION INDUSTRIES

NOT REQUIRING THE USE OF DRINKING WATER

Save costs by recycling process water in the production

Manufacturing and other industries use great amounts of drinking water in the production processes where there is no requirement it. You save a lot of money by recycling process water from your plant. In addition, you get a ‘greener’ reputation and a good story to tell to your customers and partners.

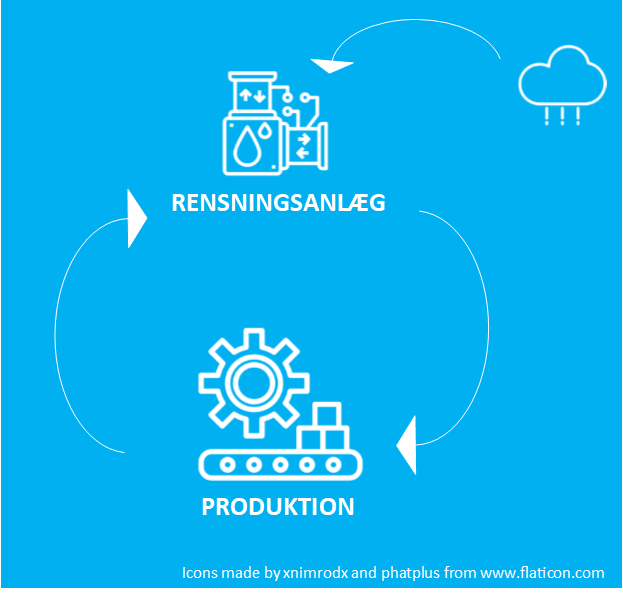

A wastewater recycling system treats wastewater from your plant and sends it back into the production, i.e. the process water circulates in a closed loop over and over again. There is no wastewater discharge from the system. All process water or wastewater is treated and reused in your plant. The system compensates water loss caused by evaporation or removal from working area by filling up with rainwater or drinking water.

Save costs by using rainwater in the production

Yes, that is right. Rainwater is for free. Why don’t you take advantage of it? Our systems are customized to harvest and use rainwater. The systems harvest rainwater from roofs and parking places.

For this purpose, there is a rainwater harvesting tank that is set up at your production building. The tank is insulated and has a direct connection to the recycling system. The process water from your plant circulates in a closed loop between the production and the system and rainwater is automatically added to the system to compensate for water loss. It cannot be much easier to save costs of water supply.

In case of long periods without rain, the system is also connected to the local water supply. So it cannot happen that there would be a lack of water.

WHAT KIND OF PROCESS WATER CAN YOU RECYCLE?

Water for cooling

Water for washing

Water for processing

Water for pressure tests

Water for product fabrication

Water for dyeing

What do you save?

What do you gain?

Costs of water supply

Costs of effluent discharge

Extra charges for discharge of highly polluted effluent

Lower production costs

Greener profile

A good story to tell

Why a recycling system from Cleantech Aqua A/S?

EFFECTIVE & COST-SAVING SOLUTION

The system recycles all process water 100 %. There is no discharge unless too much water has been

added to compensate for losses in production (evaporation, etc.).

The system uses rainwater which is for free and does not require softening.

FRIENDLY TO ENVIRONMENT

Biological methods for wastewater treatment are used where possible.

Especially the MBBRtechnique is based on the same principles as natural purification of rivers and streams in the nature.

These treatment methods do not have a negative impact on the environment.

EXCELLENT QUALITY OF THE RECYCLED WATER

Process water that has been treated in the system and is reused in the production is as clear as drinking water. The recycled water does not contain any pollutants or harmful substances.

The system treats the water to this quality endlessly.

MOBILE

Do you want to move the production?

You can take the system with you. You can lift it with a crane or forklift. You just have to drain the water from the system.

MINIMAL MAINTENANCE

The system is fully automated. It means that if you forget that you have it, it will carry on working and taking care of itself without your assistance.

The systems using MBBR technology for trade effluent treatment are self-cleaning and the water does not need to be changed. There is no need to add bacteria, they reproduce on their own.

The systems are under optimal conditions odour-free and contribute to a great working environment.

Or send us an e-mail.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.